European leaders in polystyrene construction systems

Guided by the vision of leading the change towards a circular economy, we strive to offer you the sustainable, low energy future of construction. We design our product range to help you move towards zero energy construction, whether you are building a house from scratch or just fitting out a new wetroom. We are experts in the manufacture of building systems, insulation, packaging and other special products made from expanded (EPS) and extruded (XPS) polystyrene, produced for the construction and other industries.

Get in touchWe have changed our company name to BEWI

Further to the business merger in October 2022, BEWI Construction and Insulation now heads up three market leading construction and insulation brands in the UK – THERMOMUR®, JACKODUR® and JACKOBOARD®. Commercial sales across all brands and BEWI UK’s Lancashire site continue to be headed up by Michael Hailwood, Director. Contacts within the commercial team continue as before.

Tiling with JACKOBOARD®

JACKOBOARD® is the leading UK brand of polystyrene-based construction boards and tile backerboards for wet rooms and showers, as well as other associated products for the tiling industry.

Learn moreInsulation with JACKODUR®

JACKODUR® is a premium range of extruded polystyrene insulation. It includes the best-in-class thermal properties of the PLUS range, with compressive strengths from 300 to 700kPa and is available in boards of up to 320mm thickness.

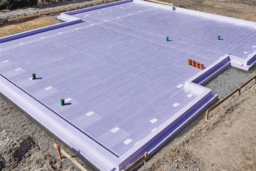

Learn moreBuilding Systems THERMOMUR® & JACKODUR® ATLAS

Our building systems include the ICF system THERMOMUR® and the insulated concrete raft system JACKODUR® ATLAS. They enable construction of thermally efficient buildings, with market leading air tightness and acoustic insulation.

Learn moreABOUT THE COMPANY

Our story

We were founded in 1956 and are proud of our history, characterised by healthy business development and continuous growth. Our slogan “Committed to sustainable construction” expresses our strong commitment to a sustainable business. Our aim is to:

- Develop long-term relationships and build common goals with our customers

- Continuously improve and develop our products and services

- To innovate energy-efficient products and environmentally friendly production – including manufacturing, distribution, product use, waste management and recycling

Latest news