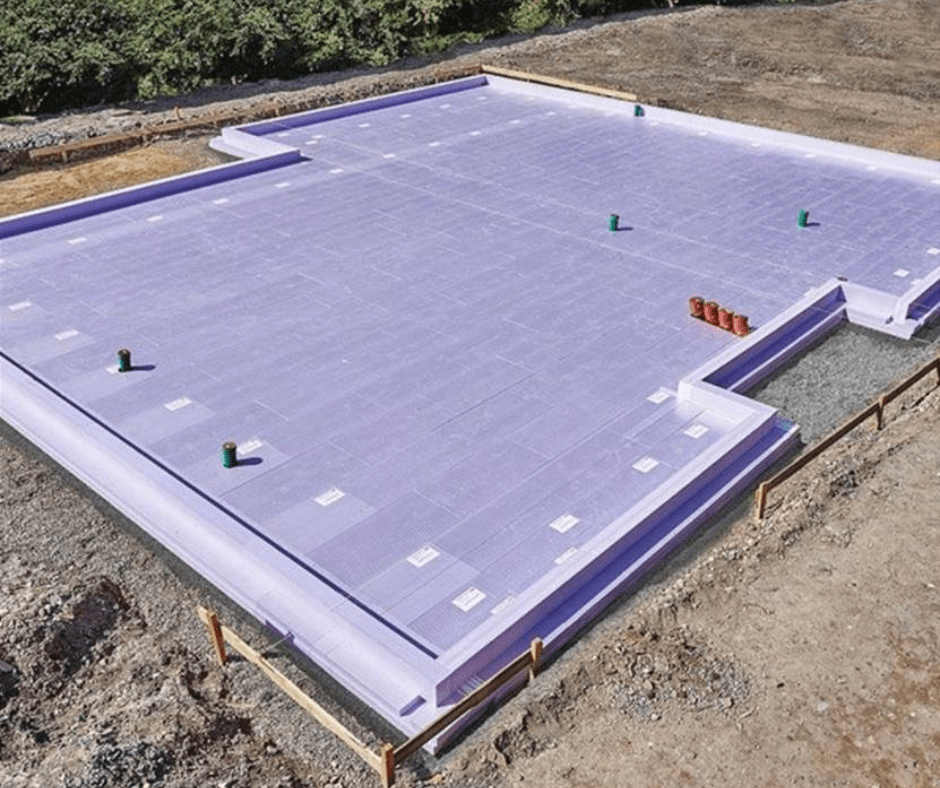

In the world of construction, time is often a precious commodity. Reducing installation time without compromising on quality is a goal shared by builders and contractors worldwide.

BEWI, a prominent provider of building insulation solutions, offers an ingenious way to achieve this with their insulation boards.

In this article, we will explore how to harness the power of JACKOBOARD® insulation boards to expedite installation time and streamline your construction projects.

Choose the Right Size

JACKOBOARD® insulation boards come in a variety of sizes to accommodate different construction needs. When selecting the size, consider the dimensions of the space you need to insulate. By choosing the right size, you minimise the need for cutting and resizing, saving both time and material.

Lightweight and Easy to Handle

JACKOBOARD®’s insulation boards are renowned for their truly lightweight nature. This feature simplifies handling and transportation. The reduced weight means that you can easily move and position the boards without straining your crew or equipment, ultimately speeding up the installation process.

Precise Cutting and Shaping

When cuts or custom shapes are required to fit the insulation boards into your specific construction design, JACKOBOARD®’s boards make the task simple. They can be precisely cut and shaped with standard construction tools. This precision saves time and ensures a snug fit.

Ready for Tiling or Cladding

JACKOBOARD® insulation boards are designed for versatility. Once installed, they are ready for tiling or cladding. This means that you can immediately proceed with the finishing touches of your project without the need for additional steps, which would typically take extra time.

Ease of Fixing

JACKOBOARD®’s boards are engineered for easy and efficient fixing. Their compatibility with various adhesives and mounting methods ensures a secure and swift installation process. Whether you’re using adhesives, screws, or other fastening methods, you can count on a smooth and hassle-free installation.

Quick Integration with Plumbing and Wiring

For projects that require plumbing or electrical work, JACKOBOARD® insulation boards can be integrated seamlessly. Cut-outs and recesses for pipes and wires can be easily created, allowing for rapid installation of these components, thus saving valuable time.

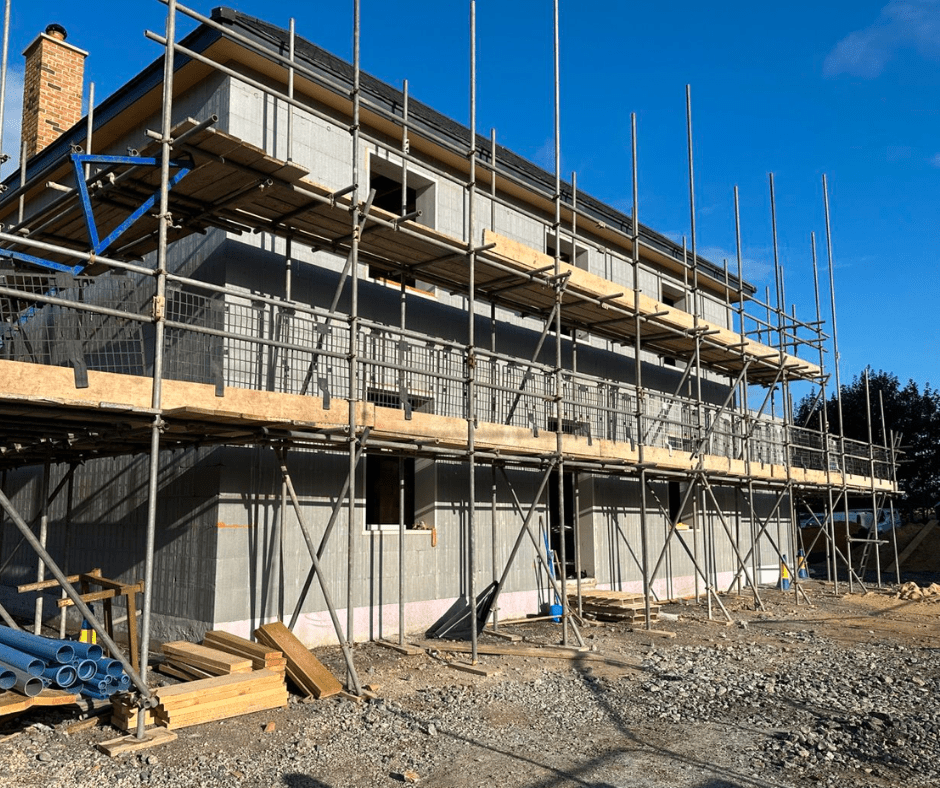

Reduced On-Site Labour

The ease and speed of installation offered by JACKOBOARD® insulation boards translate to a reduced need for on-site labour. This not only accelerates the project but also cuts down on labour costs, contributing to the overall efficiency of the construction endeavour.

Time is money in the construction industry, and using JACKOBOARD® insulation boards can be a game-changer when it comes to shortening installation time. By choosing the right size, utilising the truly lightweight and easy-to-handle boards, and taking advantage of their dry installation, precise cutting, and quick integration with plumbing and wiring, you can significantly reduce the time it takes to insulate and finish your construction project. The result is a more efficient construction process, lower costs, and the satisfaction of delivering projects on time or ahead of schedule.